Metal roofs are strong protectors of our homes, but even the toughest need help fighting off rain and rust. That’s where metal roof sealants step in, acting like a superhero’s shield against moisture to stop leaks.

Applying these protective substances can make your metal roof last up to 50 years longer! Professionals often use tools like brushes or sprayers for this job, knowing that the right conditions matter—like mild weather above 50°F without direct sunshine—so everything dries just right.

The secret to a great defense starts with preparation: clean off any dirt, get rid of old coatings, and check the materials underneath—all while making sure it’s dry as a bone. We’ll spread the sealant in critical spots like overlaps in the panels and around edges where water loves to sneak through.

And don’t forget those tiny screws—they need sealing too! Keeping an eye on these sealed areas makes sure they stay tough year after year.

Nowadays, we’ve got some nifty green products that do more than just block leaks; they cut down on repairs and reflect sunlight so you save energy! They’re part of making sure corrosion doesn’t eat away at your metal roof and keeping finishes ready for their backup role against water.

With these tips up our sleeve, we’re not only fixing problems but also extending our roofs’ lifespan significantly while helping nature out too. Ready for the full scoop? Let us show you how it’s done!

Key Takeaways

- To effectively protect your metal roof from the elements, make sure to choose a sealant that’s compatible with your roofing material, like silicone for strong adhesion or butyl-based for durability.

- Prior to applying any sealant, clean and dry the roof thoroughly to ensure the best adherence and protection against water infiltration and corrosion over time.

- Apply metal roof sealants using proper tools and techniques following manufacturer’s guidelines; allow adequate curing time to avoid leaks or premature deterioration of the product.

- Regular inspections of sealed areas on your metal roof are essential in extending its life; address maintenance promptly to prevent costly damage in future.

- Using eco – friendly options such as Liquid Rubber MetalSafe Sealant not only provides durable protection but also contributes positively towards reducing environmental impact.

Understanding Metal Roof Sealants

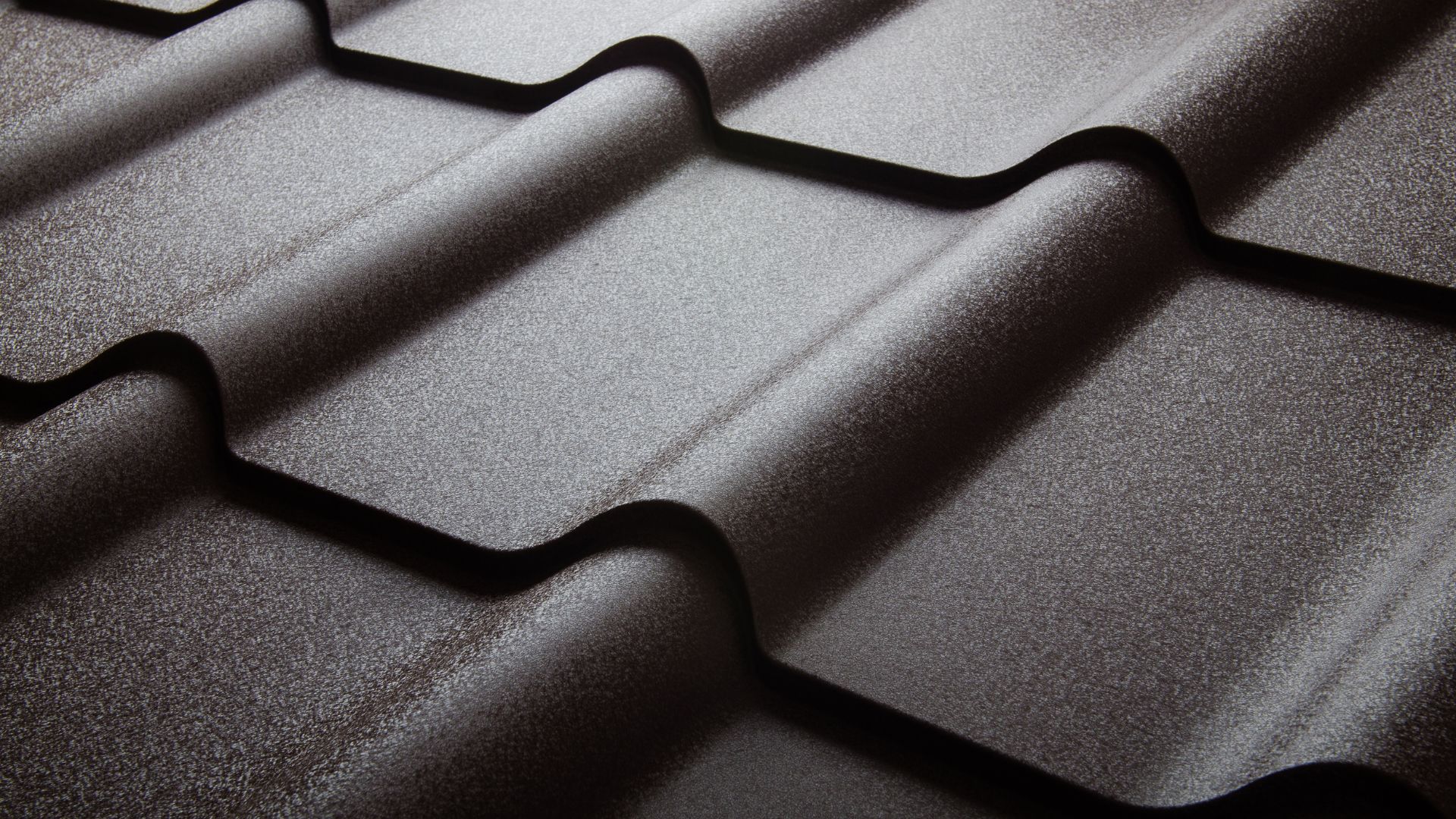

Metal roof sealants are essential for protecting our homes from the elements. They create a strong, waterproof barrier that guards against heavy rainfall, snow, and even the damaging effects of ultraviolet light.

When we apply a high-quality sealant to our metal roofs, it fills in any gaps or small holes that might allow water damage or corrosion.

Choosing the right sealant is crucial; silicone sealants offer excellent uv resistance while acrylic options are known for their energy efficiency. Butyl-based sealants provide durable seals with good adhesion, making them suitable for areas requiring extra strength like gutters and flashings.

We always make sure that our choice of metal roof sealant won’t just protect against weather conditions but also be compatible with the specific type of metal roofing material we have installed to prevent rusting and ensure long-term durability.

Types of Metal Roof Sealants

Having explored what metal roof sealants are, let’s dive into the different types available on the market. Silicone-based sealants stand out for their exceptional water resistance and durability, making them a popular choice for areas exposed to harsh weather conditions.

They create a strong barrier against moisture and can withstand extreme temperatures without cracking or degrading.

Switching gears, acrylic sealants offer an affordable alternative with easier application methods. Ideal for quick touch-ups, they can be painted over to match your roof’s color, providing both protection and aesthetics.

Butyl-based sealants bring great adhesive strength to the table, perfect for sealing under metal panels or at joins where extra hold is necessary.

Each of these options serves distinct purposes and choosing one will depend on specific needs like climate exposure and roof material type. What’s important is that all these types help maintain your metal roofing system, ensuring longevity while preventing leaks that could lead to costly damage over time.

Key Factors to Consider When Choosing a Metal Roof Sealant

As we pick out the right sealant for our metal roofs, it’s crucial to zero in on factors like compatibility with roofing materials and weather resilience. Silicone often stands out because of its strong adhesion to metals and resistance against water and temperature changes.

Butyl rubber is another go-to choice, especially for ensuring a tight gasket-like seal around fixtures due to its flexibility and durable nature.

We must balance cost-effectiveness with quality; cheaper options might save money upfront but could lead to increased maintenance or earlier replacement costs down the line. Also, consider how easy it is to apply the product—sealants requiring professional-grade caulking guns may add extra steps in our DIY projects.

With these considerations well thought out, we can steer clear of leaks and corrosion, maintaining our roof’s integrity over time. Now let’s look into “The Role of Professional Application in Sealant Effectiveness”, understanding that precise application is key for any type of sealant chosen.

The Role of Professional Application in Sealant Effectiveness

Professional application of roof sealant plays a pivotal role in ensuring its effectiveness and longevity. A skilled and experienced application process guarantees thorough coverage, strong adhesion, and a seamless finish, all of which are essential for the sealant to provide optimum protection to the metal roof.

Proper application also helps prevent potential issues like leaks or premature deterioration caused by inadequate sealing. It is crucial for property owners to recognize the significance of professional application techniques, as they directly impact the overall performance and durability of the sealant on their metal roofs.

The Three Basic Steps to Apply Sealant

Before sealing your metal roof, it’s crucial to start with a clean slate. Begin by thoroughly cleaning the roof surface to remove any dirt, grime, and debris. This step is essential for ensuring that the sealant adheres properly to the roof and provides long-lasting protection against corrosion and water infiltration.

Next, carefully inspect the specific substrate of the metal roof before applying the sealant. Take into consideration factors such as coating, paint, or bare metal as these can significantly impact the overall effectiveness of the sealing process.

Finally, ensure that the surface of your roof is not only clean but also completely dry before applying the sealant. Proper installation and adhesion of sealants require a dry surface free from moisture or other contaminants.

Taking these precautions will help you achieve optimal results when applying sealant to your metal roof while extending its lifespan and protecting your property from potential damage caused by leaks or corrosion.

Best Practices for Applying Metal Roof Sealant

To ensure the proper application of metal roof sealant, it is crucial to prepare the roof surface thoroughly, apply the sealant using appropriate tools and techniques, and allow for adequate drying and curing time.

These best practices will help maximize the effectiveness of the sealant and extend the longevity of your metal roof. Read more about these steps in our blog to protect your investment in your property.

Preparing the roof surface

Before applying metal roof sealant, it is crucial to ensure that the surface is properly prepared. This includes identifying any existing coatings or substrates and removing any flaking roof coating that could affect the adhesion of the new sealant.

Pay close attention to seals around roof seams and joints, ensuring they are intact and free from damage. Additionally, cleaning the roof surface thoroughly will aid in creating a strong bond between the sealant and the metal substrate.

Avoiding direct sunlight when applying metal roof waterproof sealant is advisable as it can impact its effectiveness.

Applying the sealant

After thoroughly preparing the roof surface, apply the metal roof sealant in a continuous and uniform manner using a brush, roller, or spray equipment. When applying the sealant, be sure to follow the manufacturer’s guidelines regarding coverage and ensure that all areas are properly coated.

Take into consideration environmental factors such as wind speed and humidity during application to achieve optimal results. Once applied, carefully inspect for any missed spots or uneven coverage and make necessary corrections promptly.

After completing the application process, allow sufficient time for proper drying and curing of the sealant before exposing it to adverse weather conditions or mechanical stress. Keep in mind that temperature fluctuations may affect drying times, so it is advisable to check the product specifications for specific guidance on this aspect.

Ensuring proper drying and curing

Before ensuring proper drying and curing of the metal roof sealant, it is crucial to understand that coatings should never be installed over wet or damp surfaces. Proper drying of the substrate is essential before applying the sealant, as any moisture trapped underneath can affect adhesion and long-term performance.

The best time to apply metal roof waterproof sealant is when weather conditions are conducive to proper drying and curing in between coats. This will ensure that the sealant can bond effectively with the surface, providing durable protection against elements such as water, UV rays, and temperature fluctuations.

It’s important to remember that allowing sufficient time for each coat to dry and cure properly will contribute significantly to the overall effectiveness of the metal roof sealant.

Importance of Maintaining Proper Sealant Joints

Proper sealant joints play a crucial role in safeguarding metal roofs from water infiltration, which can lead to costly damage and structural issues. Regular inspections and maintenance of these joints are essential to prevent leaks, corrosion, and deterioration.

By prioritizing the upkeep of sealant joints, property owners can avoid potential tenant disturbances and significant repair expenses.

Inadequately maintained sealant joints may compromise the overall weather resistance of a metal roof. This underscores the importance of proactively addressing any signs of wear or damage in these critical areas to ensure long-term protection for the building structure.

How to Seal Metal Roof Screws Quickly

To seal metal roof screws quickly and effectively, start by using a high-quality sealant that is specifically designed for metal surfaces. Thoroughly clean the screw heads and surrounding area to remove any dirt, debris, or old sealant.

Apply the new sealant generously around the base of each screw using a caulk gun, ensuring complete coverage to prevent any potential leaks. Additionally, regularly inspect and maintain these sealed areas to ensure long-lasting protection against moisture infiltration.

When sealing metal roof screws, it’s essential to use a silicone-based or weather-resistant sealant that can withstand varying weather conditions and temperature fluctuations while maintaining its integrity over time.

Regular maintenance of sealed screws will help preserve the structural integrity of your metal roof and prevent potential water damage.

Longevity and Maintenance of Metal Roof Sealants

Ensuring the longevity of metal roof sealants requires consistent maintenance. Regular inspections can help identify any areas where the sealant may be deteriorating or showing signs of wear.

By promptly addressing any issues, you can prevent water infiltration and corrosion, ultimately prolonging the life of your metal roof.

Maintaining proper sealant joints is crucial for preventing leaks and preserving the structural integrity of your metal roof. By conducting routine checks and addressing any areas that require attention, you can ensure that your metal roof remains protected from environmental elements and continues to perform at its best.

Regular maintenance not only extends the lifespan of your metal roof but also helps avoid costly repairs in the long run.

The Impact of Sealant on the Life of Piping and Appliances

Properly sealed piping and appliances contribute to their extended lifespan. Sealants play a crucial role in preventing corrosion and water intrusion, safeguarding the integrity of piping systems and appliances.

Quality sealants effectively protect against moisture, which is essential for maintaining the structural soundness of metal components, such as pipes and appliances.

Sealants also serve to reduce the risk of potential leaks that could cause damage or operational issues in both residential and commercial settings. With reliable sealant application, property owners can enhance the longevity of their piping systems and appliances while minimizing maintenance requirements.

Environmental Benefits of Using Sealant

Using sealant on your metal roof can have a positive impact on the environment. Liquid Rubber MetalSafe Sealant, for instance, is free of harmful substances and contributes to environmental conservation while extending the life of your roof.

EPDM roof sealants are resistant to weathering and UV rays, providing long-lasting protection for residential roofs without compromising environmental safety. Additionally, properly applied roof coatings contribute to reduced energy consumption by decreasing air conditioning needs and enhancing indoor comfort.

The use of silicone roof coatings provides an effective barrier against UV radiation and moisture, contributing to environmental benefits such as decreased heat island effect in urban areas and lower energy demands from cooling systems.

These environmentally friendly features make sealants an attractive option for homeowners who are conscious about reducing their carbon footprint while maintaining the longevity of their roofing system.

Tips for Selecting the Right Silicone Sealant

When choosing a silicone sealant for your metal roof, it’s essential to consider its compatibility with the specific type of metal. Look for silicone sealants specifically designed for use on metal surfaces, as they provide excellent adhesion and durability.

Consider the environmental conditions your roof will be exposed to, such as extreme temperatures or high humidity. Select a silicone sealant that offers superior weather resistance and can withstand challenging climate conditions while maintaining its integrity over time.

It’s important to choose a high-quality silicone sealant that provides long-lasting protection against water intrusion and prevents corrosion. Look for products with proven longevity and exceptional water-resistant properties, ensuring the overall effectiveness in safeguarding your metal roofing system against potential damage.

When considering different options of silicone sealants, assess their ability to resist ultraviolet (UV) exposure and prevent degradation over time. Opt for a UV-stable silicone sealant that maintains its structural integrity under prolonged sun exposure, effectively preserving the appearance and performance of your metal roof sealing systems.

The Role of Roof Sealants in Protecting Your Home

Roof sealants play a crucial role in safeguarding your home from the elements by creating a protective barrier against moisture, air, and airborne particles. They help prevent water penetration and leaks, which can lead to structural damage and mold growth if left unaddressed.

By applying an appropriate sealant to your metal roof, you can significantly extend its lifespan and ensure the integrity of your property’s interior.

Properly selected and applied roof sealants provide essential protection for both residential homeowners and commercial property managers against potential damage caused by environmental factors such as rain, snow, and UV rays.

These protective coatings serve as an effective defense mechanism that contributes to the long-term resilience of buildings. It’s important to choose high-quality sealants designed specifically for metal roofs to achieve optimal results in protecting your home or commercial property.

Next Heading: 15. Conclusion.

Conclusion

In wrapping up, understanding how to properly apply metal roof sealant is crucial for protecting your home. Taking the time to follow best practices in preparing and applying the sealant will ensure a durable and effective barrier against weather elements.

Regular maintenance of proper sealant joints and utilizing the right silicone sealant can further enhance the protection provided by roof sealants, ultimately extending the lifespan of your roof and safeguarding your property.

If the content of the linked page had been relevant to any specific point, it would have been included under the relevant section. )

Choosing the right metal roof sealant is crucial for addressing leaks at flashing areas and avoiding common problems. Failed sealant or butyl tape often cause leaks in standing seam metal roofs, emphasizing the importance of selecting specific types of metal roof sealants tailored to this roofing system.

PERMAKOTE® SILVER SEAL, known for its excellent adhesion on most interior and exterior surfaces, including weathered wood, shakes, plywood, primed metal, and clapboard offers a suitable solution.

By following best practice guidelines for installing metal roof sealant and addressing specific corrosion issues with appropriate coatings, homeowners and property managers can effectively maintain their metal roofs’ integrity.

Ensuring proper application of high-quality sealants targeted towards addressing roofing challenges such as corrosion issues is essential in preserving the longevity of your building’s roofing system.

To learn more about roofing options and how they can benefit your commercial property, check out our comprehensive guide on the [lowdown on commercial flat roofing benefits and options](https://roofingbylandmark.com/lowdown-commercial-flat-roofing-benefits-options/).

FAQs

1. Why is sealing a metal roof important?

Sealing a metal roof is crucial because it prevents leaks that could corrode the structure and cause heat loss, ensuring the building envelope stays intact for green building standards.

2. What kind of sealant works best on metal roofs?

Silicones are often preferred by the Metal Building Manufacturers Association due to their durability and effectiveness in sealing joints on both flat roofs and pre-engineered metal buildings.

3. Should I clean my roof before applying sealant?

Absolutely, cleaning your roof with care removes debris and ensures that the sealant adheres correctly to materials like zinc or copper, which might be part of your roofing system.

4. Can sealants be used with other roofing materials like asphalt shingles or batt insulation?

Yes, you can apply specific types of sealants designed to work with asphalt shingles as well as around areas where batt insulation is installed to prevent any gaps within the framing.

5. Are there any codes or guidelines I should follow when applying sealant to my metal roof?

You should always adhere to International Building Code (IBC) standards when applying sealant for proper installation techniques such as using hose clamps or EIFS (Exterior Insulation Finish Systems) on curbs while preventing issues like water infiltration.

Contact Us

After starting his first business at age 26, Artie Hendricks partnered with his best friend Rob Calhan and they have assembled a team of skilled and conscientious friends to be the core of Landmark Roofing. He largely credits his father’s strong and consistent work ethic and his father’s best friend Jerry, who owns a construction company and trained him through his first building experiences. Artie has since advanced through degrees in architecture, auto-CAD and construction management to build a business that prides itself on the care it shows for its work and its customers’ satisfaction.